Remote Monitoring Solutions for Food Service Operations

Put Food Safety First for Your Customers

Your quality food keeps customers coming back. But if you suffer a cold storage failure, or if manual temperature checks and paper logs lapse, how fast could you recover from a health code violation or inventory loss? Food spoilage or a single missed refrigerator check can shut down operations and cost thousands in lost product.

Eliminate spoilage. Keep temperatures in the safe zone.

Monitoring storage, cooking, and serving conditions to protect your customers – and to stay compliant – is easier with automation. The U.S. Food and Drug Administration’s Food Safety Modernization Act (FSMA) introduced stricter requirements for monitoring and record-keeping that can be challenging to meet manually. myDevices’ wireless sensors and cloud platform help you fast-track compliance by automating temperature logging and alerts.

Effortlessly monitor temperature and automatically create Hazard Analysis Critical Control Point (HACCP) -compliant digital logs of your food storage data. Our system supports electronic records management and meets FDA 21 CFR Part 11 requirements for data integrity. In other words, all temperature records are securely stored, time-stamped, and tamper-proof for audits and inspections.

With myDevices, you can automate temperature checks across all your equipment and facilities. Receive real-time alerts for any out-of-range condition—whether a cooler warms above safe temperature (e.g. above 40 °F (4 °C) ), a freezer fails overnight, a walk-in door is left open, or a power outage occurs. Critical data (temperature, humidity, etc.) is continuously captured and sent to the cloud for easy access from anywhere . By eliminating manual logs and human error, you gain peace of mind that your inventory stays safe even when staff are off-duty. If an issue arises, designated staff are immediately notified via text, email, or call, so they can take corrective action before food quality is compromised.

Schedule a Demo to see how myDevices can safeguard your operations and keep your kitchen running smoothly and safely.

Comprehensive Sensor Coverage for Kitchen & Storage

myDevices offers a wide range of wireless sensors to cover every critical aspect of food service environments. Deploy the sensors you need to monitor all your important equipment and conditions:

All our sensors are wireless and battery-powered for easy installation, with battery life often spanning multiple years. They communicate to a gateway device that sends data to the myDevices cloud. You can configure the logging interval (for example, record temperature every 15 minutes or every hour, as needed) to balance granularity with battery life. Crucially, if network connectivity or power is ever lost, the sensors will fail-safe: each device can internally log readings and then forward that data once the connection is restored . This means no data gaps – you’ll have a complete record of conditions before, during, and after any incident.

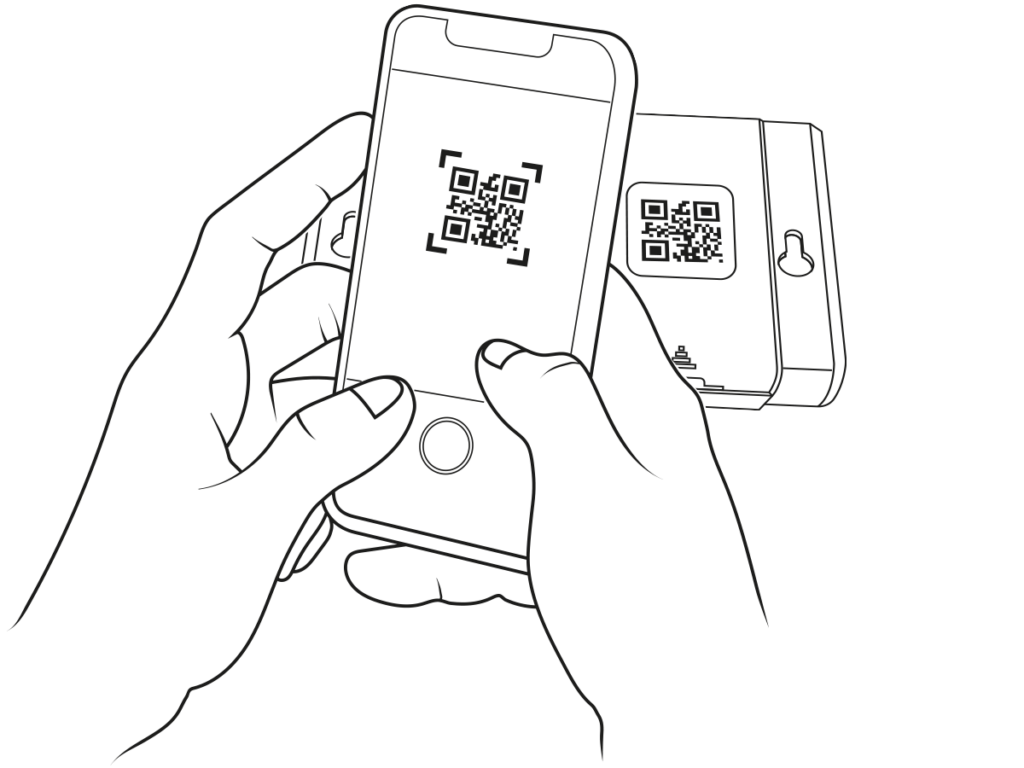

Deploy in Minutes – How It Works

1Choose Your Sensors

2Install & Connect

3Configure & Monitor

Proven Results in Food Service Environments

Schedule a Demo Today

Solutions for every need.

Let’s Connect

This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.